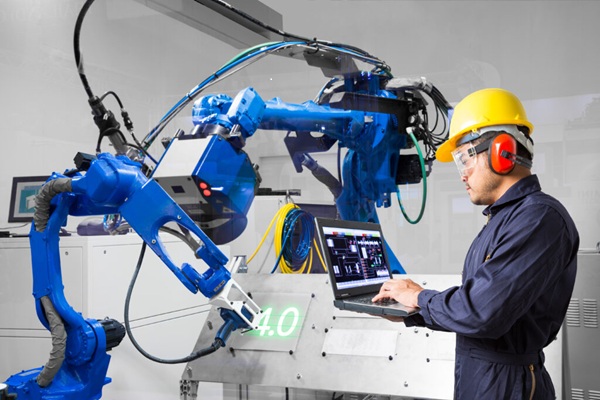

In today’s industry 4.0 , Industrial automation requires ultra-reliable platforms to ensure uninterrupted and stable equipment and system operations and data integrity. From monitoring equipment status to optimizing workflows, factories depend on real-time data collection, storage, and processing to keep operations running smoothly.But harsh industrial environments—high heat, vibration, dust, and power fluctuations—push storage systems to their limits.

When storage fails, the risks are serious: production downtime, data loss, or even costly system outages. That’s why choosing industrial-grade SSDs—built for wide temperature ranges and rugged reliability—is essential for keeping your production lines moving without interruption.

Why Wide Temp SSD Industrial SSDs Matter

Unlike consumer drives, Industrial SSDs are engineered for extreme conditions. Whether you’re integrating a 2.5″ SATA SSD into legacy equipment or a compact M.2 SATA SSD into modern automation systems, these drives offer Enhanced Reliability & Endurance, Environmental Toughness ,High Data Security and Fixed Bill of Materials (BOM) industrial applications demand.

1. Wide Temperature Performance

Operates reliably from -40°C to +85°C, with no risk of data loss or system errors.

Tested against MIL-STD-810F/G anti-vibration and shock standards, ensuring stable performance on factory floors with constant motion.

2. Enhanced Reliability & Endurance

Equipped with power loss protection, industrial SSDs safeguard data during sudden outages or voltage drops.

Long endurance cycles and advanced error correction ensure consistent performance in 24/7, high-write environments.

3. Compact & Flexible Form Factors

2.5 SATA SSDs deliver robust compatibility with existing industrial PCs, IPC Embedded PC and Surveillance system in today’s IoT (Internet of Things) applications.

Industrial M.2 SSDs (M.2 SATA and NVMe options) offer smaller footprints for next-generation automation devices, Industrial Panel PC, Rugged PC and Industrial AGV( Automated Guided Vehicle)

4. Designed for Harsh Environments

Built with dust-proof, moisture-resistant, and corrosion-resistant housings.

Resistant to mechanical shock and continuous vibration, making them ideal for robotics, transportation systems, and heavy manufacturing equipment.

Applications in Industrial Automation

Industrial SSD drives are now the trusted storage backbone across multiple automation environments:

Factory automation – real-time sensor data logging, machine control, production tracking.

Industrial PCs – stable platforms for monitoring, testing, and controlling processes.

Robotics and motion control – rugged ssd drives withstand constant vibration and shock.

Transportation and energy systems – reliable storage in high-heat, wide-temperature outdoor settings.

Summary

In industrial automation, storage is more than capacity—it’s the heartbeat of uninterrupted operations. By deploying Wide Temperature SSDs—whether 2.5 SATA SSDs or Industrial M.2 SSDs—manufacturers gain confidence that their systems will run continuously, even under extreme environments.

At Indudisk, our Industrial Grade SSDs combine High Performance & Low Latency, Enhanced Reliability & Endurance, Environmental Toughness That means stronger uptime, safer data, and smoother production flows.

Because in automation, just like in aerospace or defense, failure is not an option.

🚀Indudisk Military SSDs are built for extreme environments where compromise isn’t an option.