Industrial SSD

Indudisk Industrial SSDs provide higher reliability ,higher durability and lower cost compared to others.

16GB~1TB

Indudisk M.2 SSDs with SATA and PCIe interface are designed to meet the

requirements of embedded and NetCom applications. All Indudisk industrial SSDs are highly reliable and durable, optimized for low cost.

128GB~2TB

Indudisk’s Industrial mSATA SSD comply with JEDEC MO-300A specifications and is fully suitable for industrial applications, embedded computing devices.It is designed for robustness against high shock and vibration.

128GB~2TB

Indudisk SLIM SATA (MO-297) ,mSATA and M.2 SSDs target embedded applications which require solid state storage in small, removable form factors.It is an ideal solution for Marine and Industrial Compact Equipment.

128GB~2TB

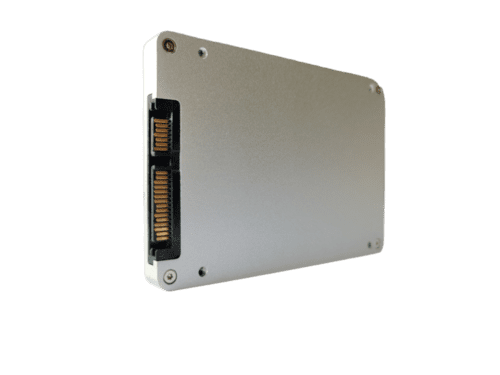

Indudisk industrial 2.5” SATA SSDs are ideal solutions for embedded applications requiring reliable and long service life storage.Indudisk 2.5″ SATA I6 Evo Series is based on latest 3D NAND TLC with focus on best TCO.

8GB~256GB

Indudisk SATA DOM is compact in size and available with horizontal connectors for high compatibility and is equipped with MLC NAND flash for high durability and reliability with a 3K P/E cycle rating .

8GB~256GB

Indudisk Industrial CF Card delivers high reliability and high durability for industrial and military applications.They are specially designed with the highest MLC/SLC Flash for applications which demand data integrity and 100% uptime.

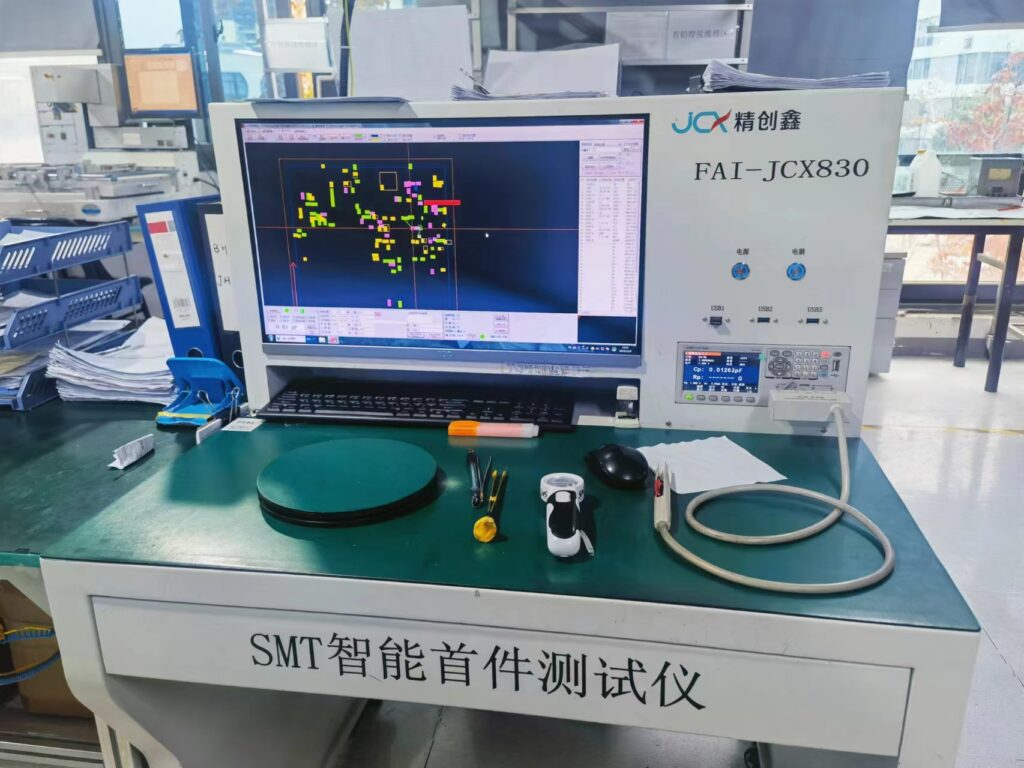

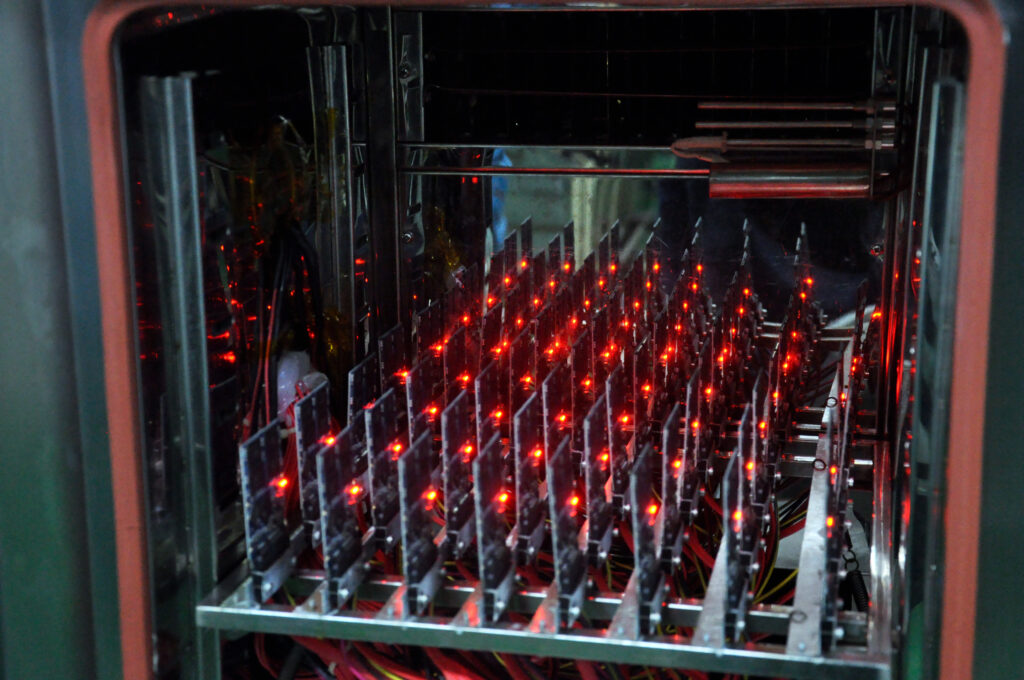

Quality Assurance and Manufacturing Process

At Indudisk, Quality is First.From raw material to finished products,we employ a higher standard at every step of IQC and testing. Strict tests and inspections are conducted to guarantee each SSD drives are in perfect condition before shipping.We deligently strive to ensure 100% customer satisfication with our Industrial grade SSD and Military Grade SSD products.

Ask us about our products

At Indudisk, We offer a wide range of industrial SSDs and military SSDs in a variety of form factors.Learn more and request a free quote now.

How to choose the right Industrial SSD

SSD Sizes, Interfaces, Types, Uses ,Features and More

Q1: HDD vs SSD

Before SSD technology emerges, HDD is the main storage device . HDD is a traditional hard drive consists of a spinning disk with a read/write head on a mechanical arm called an Hard Disk. An HDD reads and writes data magnetically. The magnetic properties, however, can lead to mechanical breakdowns.

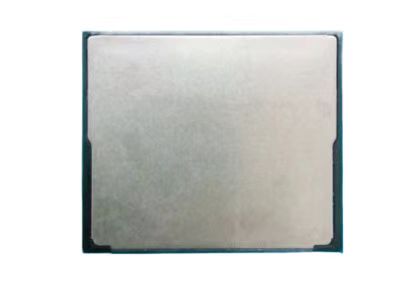

While SSD is a non-volatile storage media that stores constant data on solid-state Nand Flash chips. Now SSDs are replacing traditional HDD in computers as storage device. Because SSDs are much faster in comparision .With an SSD, the device ‘s OS will boot up more quickly ,Programs will load quicker and files can be saved faster.

Since an SSD has no moving parts to break or spin up or down. The two key components in an SSD are the flash controller and NAND flash memory chips. This configuration is optimized to deliver higher read/write performance for sequential and random data requests. Also, the data is stored in the flash memory safely and the SSD delivers higher reliability than traditional HDD.

Q2: What application do you use the SSD for ?

As an SSD buyer, it is very key to choose the right SSD product at favorable price for your project. But do you know how to choose a right SSD solution for your projects ? As an SSD expert, the starting point is to learn about your application. For example, what is your operating temperature ?Is it used as a system drive or mass capacity data transfer ? Is it mainly used for read or write operations ? What OS ? Since all answers above related to your application is very pivotal to select a right SSD that aligns perfectly with your requirements and uphold unwavering quality.

Q3: What is the Operating Temperature for Industrial SSDs and Military SSDs?

Most people are still confused to select a right SSD type . Generally speaking, this greatly depends on the operating temperature range of your application environment for the SSD. As an SSD manufacturer ,Consumer SSDs/Commercial SSDs are designed to operate at temperatures ranging from 0 degrees Celsius to 70 degrees Celsius , Industrial SSDs are designed to operate at temperatures ranging from -20 degrees Celsius to 70 degrees Celsius while military SSDs/rugged SSDs are designed to operate at temperatures ranging from -40 degrees Celsius to 85 degrees Celsius.

Generally Speaking, we can differ Industrial SSDs from military SSDs by their Operating Temperature as below:

- Commercial Temperature: 0C to +70C

- Industrial Temperature :-20C to +70C

- Military Temperature : -40C to +85C

Q4: Which is better SSD TLC or MLC or SLC ?

If you are exploring your options for industrial flash storage, two contenders are likely to be on your list: SLC NAND and MLC NAND. Both forms of NAND flash storage are popular and reliable, and each one has its most appropriate uses. The trick is not using MLC NAND when you really need SLC, or paying for SLC when you could get by with MLC. Which NAND flash storage technology is right for your application? This comparison of SLC NAND vs. MLC NAND will help you make up your mind.

With SLC NAND, one bit of data is stored on each cell. This kind of storage is extremely important for devices in which critical data will be saved.It provides suitable reliability and greatly minimizes the risk of data loss and corruption.

With MLC Nand,MLC stands for multi-level cell with two bits of data are stored per cell.You will find it most often in commercial and industrial applications. MLC NAND is the right solution for these products because it costs less than SLC NAND.

SLC and MLC flash mermory are similar in their design. MLC SSDs cost less and allow for higher storage density. SLC SSDs provide faster write performance and higher reliability.

With TLC Nand, a triple-level cell NAND flash, stores three bits of data per cell.It is ideal for consumer grade products because the price point of TLC flash is the lowest of these three forms.

As for SSD endurance, SLC SSD is rated at approximately 100,000 PE cycles per cell. SLC SSD is is rated at approximately 10,000 PE cycles per cell. TLC SSD is rated at approximately 3,000 PE cycles per cell.While QLC is rated at approximately only 1,000 PE cycles per cell.

Q5 : What is the SSD form factor M.2 ,2.5″,mSATA and U.2 ?

An SSD form factor is the size, configuration or physical arrangement of solid-state storage media.The form factor determines the media’s physical compatibility and interchangeability with other computer components or devices.

2.5″

when buying an SSD, the first thing you want to know is which form factor fits your system. SSDs come in a variety of form factors. For example,2.5″ is the most common type of SSD and fits into most laptop or desktop computers.It has a similar shape to a traditional HDD and connects over SATA cables so it offers a very familiar experience to what many are already used to.

M.2

M.2 has become the standard type of storage for slim laptops and notebooks.Its tiny form factor is often compared to a stick of gum and easy to install right on the motherboard in most cases. It is available in various lengths to enable different SSD capacities, The longer the drive,the more Nand flash chips can be mounted on it leading to higher capacity SSDs.

mSATA

mSATA or mini-SATA,is essentially a smaller version of the full-size SATA SSD,It uses a compact form factor like M.2 but not interchangeable.M.2 SSD can support both SATA and PCIe interface options whereas mSATA only supports SATA. This form factor is designed for smaller form factor systems where space is limited.

U.2

Finally,there’s U.2 which looks like a 2.5″ drive but it is a bit thicker .It uses a different connector and sends data through the PCIe interface.U.2 SSD is typically used for high-end workstations,servers and interprise applications that need greater storage.It allows higher operating temperatures and is more favorable for transferring heat than M.2 form factor.

Q6: What is the difference between M.2 and NVMe SSD ?

While M.2 and NVMe are popularly used now,they actually refer to different technologies that can be used together but:

- NVMe is a storage transfer protocol specially designed for high-performance,non-volatile storage media.

- M.2 is an SSD form factor that enables high-performance storage.

- M.2 SSD connected using the NVMe interface deliver faster read/write speed

M.2 SATA SSDs use the SATA interface with a max. data transfer of 6Gbps. This is slow compared to the new NVMe intefaces. But it have 3 to 4 times the bandwidth compared to traditional HDD and is more available and affordable than a NVMe SSD. So it is a great alternative

M.2 NVMe SSDs are much more performance driven compared to M.2 SATA SSDs. By leveraging the PCIe bus, M.2 NVMe SSDs have theoretical transfer speeds of up to 20Gbps which is already faster compared to M.2 SATA SSDs with 6Gbps. PCIe buses can support 1x, 4x, 8x, and 16x lanes.

Industry Standards

Indudisk SSD follow certain standards such as CE,FCC, IS09001:2018 standards.With that in mind, there are strict standards for the material of industrial SSD. We insist on using the superb orignial flash and DRAM ICs,top-quality industrial components and well-equipped manufacturing equipments and self-deployed automatic testing equipments to ensure high quality ,consistency and efficiency.The Indudisk QMS (Quality Management System) goes above & beyond industry standards. We believe in 100% visibility and 100% traceability. We accept no compromises.

Get an Instant Quote For your Upcoming Projects Today?

Get an instant quote or let us know what you’re looking for and we’ll get back to you soon within 24h.